Our promise is to make work safe.

Our philosophy focuses on people. For us, the technological benefits for workers are paramount.

Under the ANGEL React brand, we create state-of-the-art emergency systems for lone workers. Our superheroes, the ANGEL React Clip system and the ANGEL React Shirt system, reliably react to workplace accidents and call for help. The Watchdog quickly powers off voltage sources, and the Location Beacon ensures higher accuracy in indoor location positioning.

We use technology and our experience to improve the world of occupational safety.

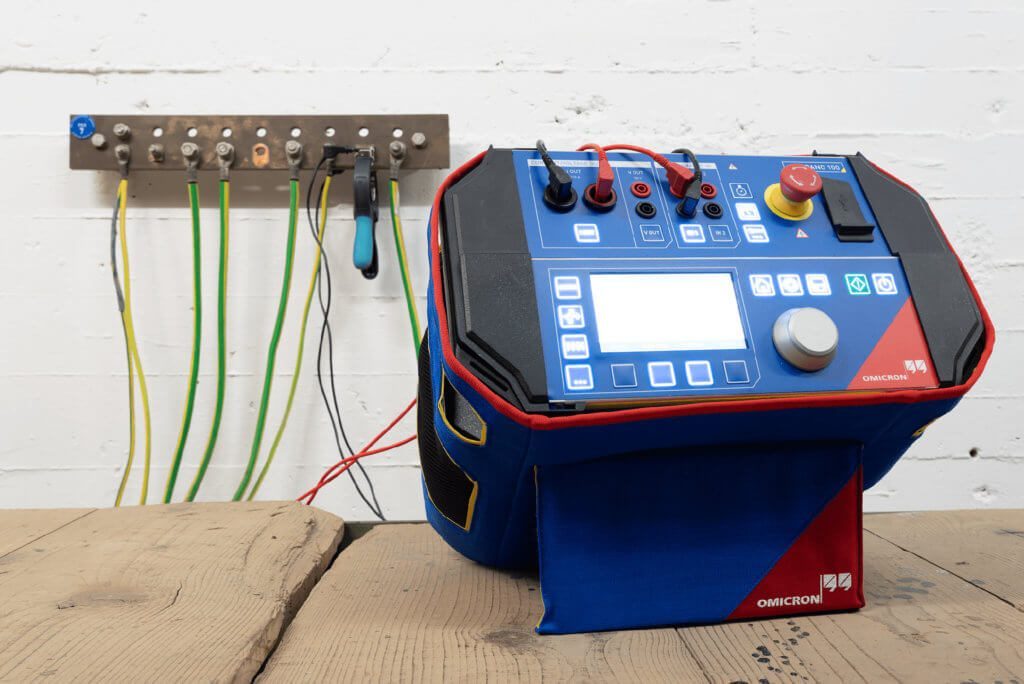

At our innovation site in Salzburg, our development team creates solutions and products for our parent company, OMICRON electronics GmbH, the world market leader in innovative solutions for testing, analyzing, and diagnosing equipment in energy technology.

We work with great passion on revolutionizing the smart textile solutions industry.

ADRESYS

ADRESYS  ADRESYS

ADRESYS  ADRESYS

ADRESYS  ADRESYS

ADRESYS